Upgrade your existing tank with Kest's magnetic coupled mixers for your critical Pharma and Biopharma Applications.

A unique solution designed to optimize your existing tank systems for critical pharmaceutical and biotechnology processes. This innovative programme allows you to seamlessly upgrade and reuse your existing tank plates with Kest Mixers, unlocking a new level of performance and flexibility. Not only does this solution make switching mixers simple, but it also allows you to harness the full range of advanced features that Kest Mixers offer, delivering superior mixing performance, increased operational efficiency, and reliability for even the most demanding applications.

Future-proof your processes with BioPulse’s Kest Retrofit Programme—efficiency and innovation, engineered for success. Simply fit a Kest mixer to your current tank plate

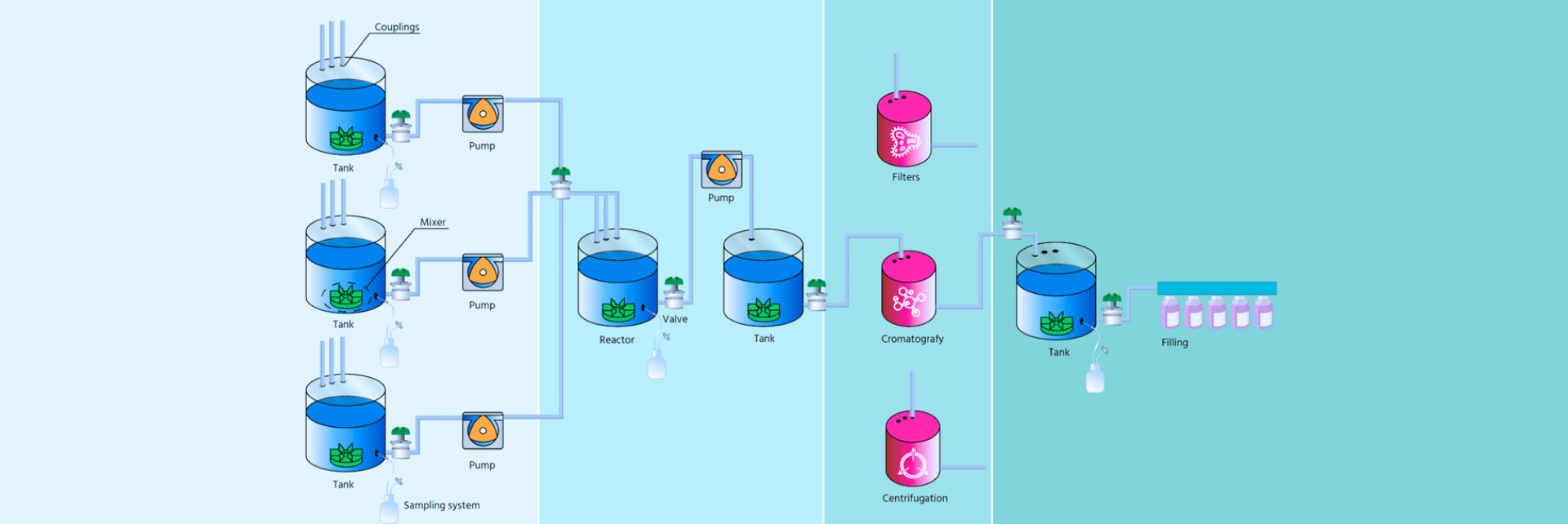

Upstream

Media Preparation

Buffer Preparation

Process

Cell Culture

Fermentation

Downstream

Harvesting

Formulation/Filling

Purification

unit operations

Advantage Kest Retrofit Program - Powered by BioPulse

Quality Components - With a SEAMLESS FIT!

Tank Integrity Maintained

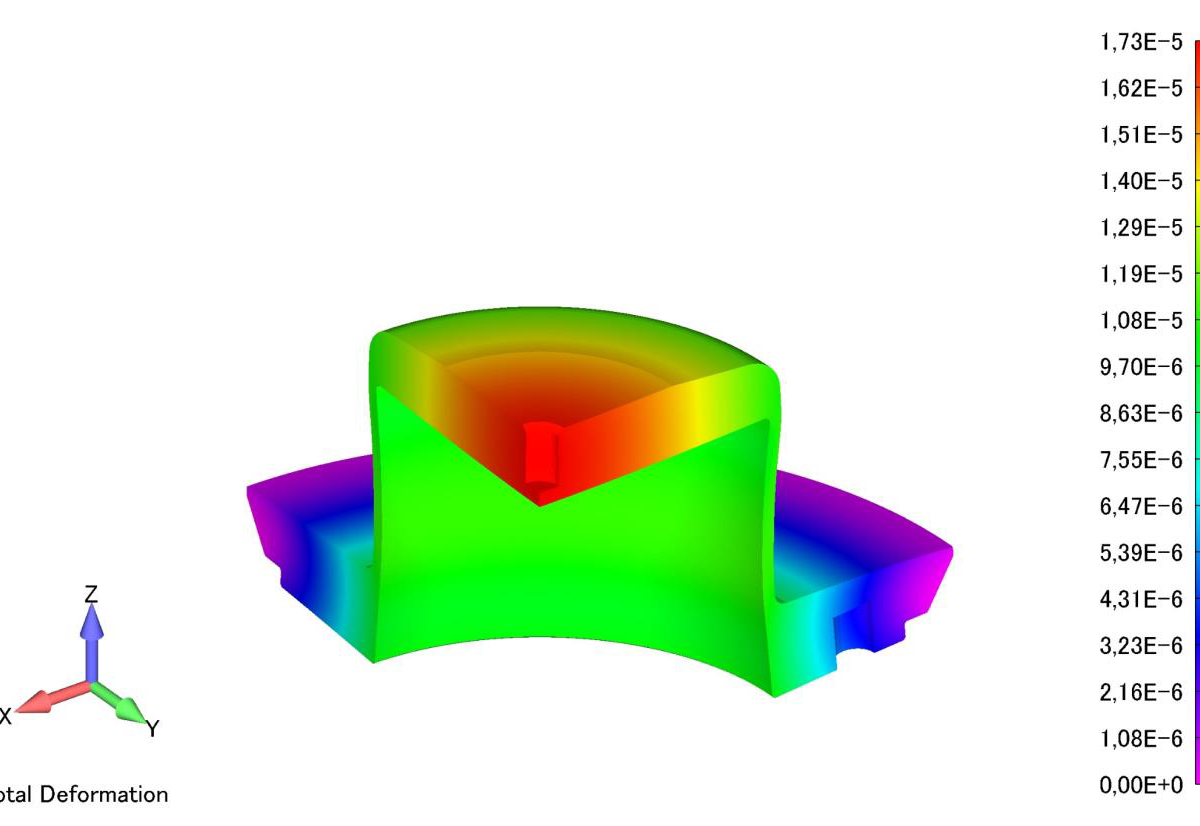

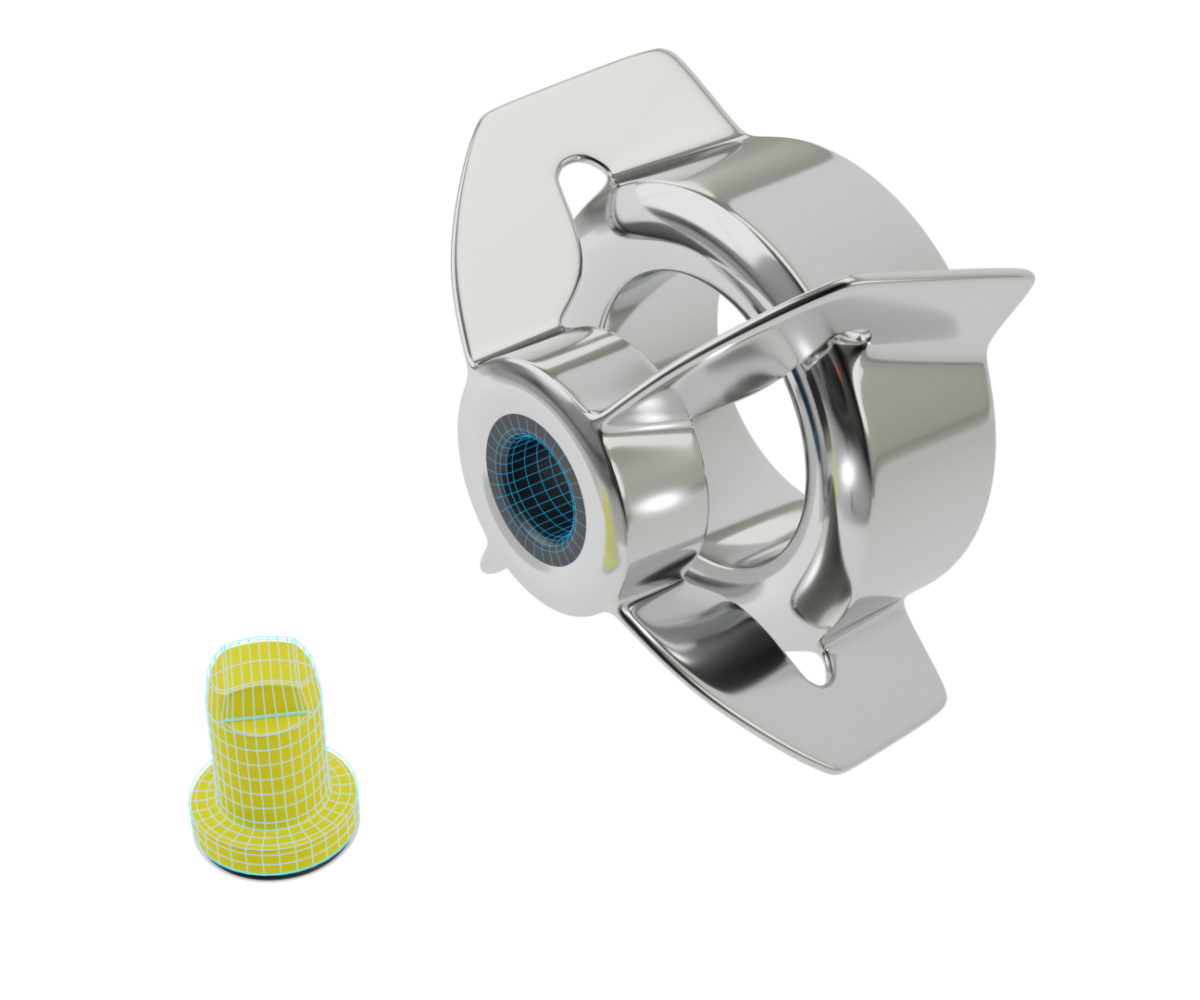

The Kest Mixer Tank Plate, machined from a solid bar and FEM-analyzed, meets PED and ASME pressure vessel codes. Welded securely into the tank, it ensures a contamination-free barrier for your media.

Full Product Recovery

Unique head design, with blades positioned near the tank bottom, ensures efficient mixing to the last drop while maintaining uncompromised cleanability. Its low-profile design and wide wing area make it ideal for continuous mixing, even at low liquid levels.

Zero particle Shedding

The Kest Mixer Tank Plate, machined from a solid bar and FEM-analyzed, meets PED and ASME pressure vessel codes. Welded securely into the tank, it ensures a contamination-free barrier for your media.

Reduced Downtime

The Kest Mixer’s patented Kest-Lock connection allows quick, secure disconnection of the drive unit for maintenance, simplifying reattachment with a spring-closed mechanism. Larger models feature a lowering device for easy mixing head inspection without removing the drive unit.

Full Process Control

The Kest Mixer can be equipped with an intelligent speed sensor system that monitors the mixing head’s movement, speed, and direction using magnetic fields. This ensures precise control and validation of your mixing process.

Conversion table

The table below shows which Kest Mixer corresponds to your GMP tank plate size. If you need assistance in selecting the right mixer or have any questions, our team and trusted partners are here to help. Don’t hesitate to reach out—we’re ready to support your needs!

| KEST SIZE | TANK PLATEGMP Mixer |

|---|---|

| 0/3 | - |

| 3/7 | GMP 50 |

| 7/20 | GMP 100 |

| 20/70 | GMP 500 |

| 70/120 | GMP 1000 |

| 120/230 | GMP 2000 |

| 230/600 | GMP 5000 |

| 600/1300 | GMP 10000 |

| 1300/2200 | GMP 20000 |

We are Experts in Fluid Handling, Open Architeture Single-use Bioprocessing Solutions and Hose Assembly Manufacturing

BioPulse Solutions specializes in fluid paths and Fluid handling solutions, delivering world-class Open Architecture Solutions, and Service for the global biopharmaceutical and pharmaceutical industries. Our innovative solutions combined with our expertise ensue customers flexible and economical solutions for their proces scale-up and optimization projects.